Dubai, a global hub for innovation, is rapidly embracing 3D printing technology, which is revolutionizing product design and prototyping across various industries. The adoption of 3D printing in Dubai has significantly accelerated the design and prototyping processes, providing businesses with a competitive edge in terms of speed, efficiency, and flexibility.

This article explores how 3D printing in Dubai influences the speed of product design and prototyping, highlighting the key factors that contribute to this transformative impact.

Rapid Prototyping and Iterative Design Process

One of the most significant ways 3D printing influences the speed of product design in Dubai is through rapid prototyping. Traditional prototyping methods often involve lengthy and costly processes, such as creating molds, machining parts, or outsourcing production. These steps can take weeks or even months to complete, delaying the overall product development timeline.

In contrast, 3D printing allows designers in Dubai to create prototypes directly from digital models within hours. This rapid prototyping capability enables businesses to quickly test and refine their designs, leading to faster iterations and improvements. The ability to produce multiple prototypes in a short period allows for more experimentation, ultimately resulting in better-designed products that can be brought to market faster.

Streamlined Design-to-Production Workflow

3D printing significantly streamlines the design-to-production workflow, further enhancing the speed of product development in Dubai. Traditional manufacturing processes often involve multiple stages, such as tooling, setup, and assembly, each of which can introduce delays. Additionally, these processes may require coordination between different suppliers, adding complexity and time to the project.

With 3D printing Dubai, the entire process—from design to production—can be consolidated into a single, seamless workflow. Once a digital model is created, it can be sent directly to a 3D printer, bypassing many of the intermediate steps required in traditional manufacturing. This streamlined workflow reduces lead times and minimizes the potential for errors or miscommunication, allowing products to move from concept to production more quickly.

On-Demand Manufacturing and Reduced Lead Times

Dubai's dynamic business environment demands agility and the ability to respond quickly to market changes. 3D printing enables on-demand manufacturing, which plays a crucial role in reducing lead times for product design and prototyping. Traditional manufacturing often requires large production runs to justify the costs of tooling and setup, leading to longer lead times and potential delays in bringing products to market.

In contrast, 3D printing allows for the production of small batches or even single units as needed, without the need for extensive setup or tooling. This on-demand capability means that designers and manufacturers in Dubai can quickly produce prototypes, make adjustments, and iterate on designs, all within a much shorter timeframe. As a result, companies can rapidly respond to customer feedback, market trends, or technological advancements, maintaining a competitive edge.

Enhanced Collaboration and Design Flexibility

Collaboration is a critical component of successful product design, and 3D printing facilitates enhanced collaboration by providing designers, engineers, and stakeholders with tangible prototypes early in the development process. In Dubai's fast-paced business environment, the ability to quickly produce and share physical models helps teams make informed decisions and refine designs more efficiently.

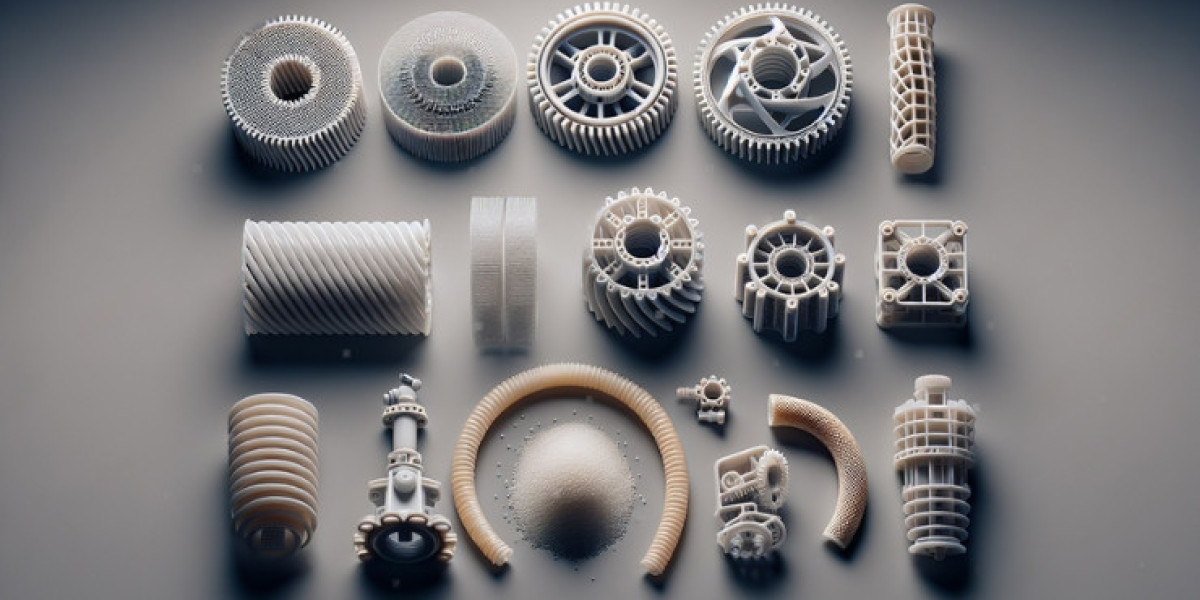

3D printing also offers greater design flexibility, allowing for the creation of complex geometries and intricate details that may be difficult or impossible to achieve with traditional manufacturing methods. This flexibility enables designers in Dubai to explore innovative design concepts without being constrained by the limitations of traditional production techniques. The ability to quickly prototype and test these designs accelerates the overall product development process, leading to faster time-to-market.

Cost-Effective Prototyping and Design Iteration

The cost of prototyping and design iteration is another factor that influences the speed of product design in Dubai. Traditional prototyping methods can be expensive, particularly when multiple iterations are required. The cost of creating molds, machining parts, or outsourcing production can add up quickly, leading to budget constraints that may slow down the development process.

3D printing offers a cost-effective alternative, allowing companies in Dubai to produce prototypes at a fraction of the cost of traditional methods. This affordability enables more frequent iterations and refinements, leading to better-designed products in a shorter timeframe. The reduced cost of prototyping also makes it feasible for startups and small businesses in Dubai to compete with larger companies by bringing innovative products to market more quickly.

Accelerated Innovation and Market Responsiveness

In an increasingly competitive global market, the ability to innovate and respond to customer needs quickly is essential. 3D printing empowers companies in Dubai to accelerate innovation by reducing the time required to bring new ideas to life. Whether it's developing a new product feature, testing a novel design concept, or responding to customer feedback, 3D printing allows businesses to iterate quickly and efficiently.

This accelerated innovation cycle enables companies in Dubai to stay ahead of the competition by rapidly adapting to market demands and trends. The speed at which products can be designed, prototyped, and refined using 3D printing technology translates into faster time-to-market, giving businesses a significant advantage in capturing market share and driving growth.

Future Prospects of 3D Printing in Dubai's Product Design

As Dubai continues to invest in 3D printing technology, the future prospects for product design and prototyping look promising. The Dubai 3D Printing Strategy aims to position the city as a global leader in 3D printing, with a focus on industries such as construction, healthcare, and consumer goods. As the technology continues to evolve, we can expect even greater speed, efficiency, and flexibility in product design and prototyping.

Innovations such as multi-material 3D printing, faster printing speeds, and advanced software tools will further enhance the ability of companies in Dubai to rapidly develop and refine products. Additionally, the increasing availability of local 3D printing services and materials will help reduce lead times and costs, making the technology more accessible to businesses of all sizes.

Conclusion

3D printing is having a profound impact on the speed of product design and prototyping in Dubai. By enabling rapid prototyping, streamlining workflows, and offering on-demand manufacturing, 3D printing allows businesses to bring products to market faster and more efficiently than ever before.

The technology also enhances collaboration, design flexibility, and cost-effectiveness, further accelerating the development process. As Dubai continues to embrace and invest in 3D printing, the city's position as a global hub for innovation and product design will only strengthen, driving continued growth and competitiveness in the years to come.