Increasing demand for oil and gas: The wired drill pipe market is primarily driven by the growing demand for oil and gas. As energy needs continue to rise, oil and gas companies are increasingly turning to innovative technologies like wired drill pipes to improve drilling efficiency and reduce costs.

Advancements in drilling technologies: With the development of advanced drilling technologies, the wired drill pipe market is expected to grow significantly in the coming years. New technologies such as rotary steerable systems and downhole sensors are driving the demand for wired drill pipes, as they require reliable real-time data transmission from the bottom of the well.

Growing focus on offshore exploration: The offshore drilling sector is a major driver of the wired drill pipe market, as these operations require high precision and accuracy. Wired drill pipes are ideal for offshore drilling, as they provide real-time data and help operators to monitor drilling conditions and make informed decisions.

Increasing focus on cost reduction: In an increasingly competitive market, oil and gas companies are looking for ways to reduce costs while maintaining high levels of productivity. Wired drill pipes help to achieve this by reducing downtime and increasing drilling efficiency.

Government regulations and environmental concerns: Governments around the world are imposing stricter regulations on oil and gas drilling activities, which has led to increased demand for wired drill pipes. Wired drill pipes can help companies to meet these regulations by reducing the environmental impact of drilling activities and improving safety.

Wired Drill Pipe Market Overview:

Wired drill pipe is a type of drill pipe that has a cable running through it, which enables communication between the surface and downhole equipment. The cable is usually made of high-strength steel and is protected by a durable outer layer to ensure that it can withstand the harsh drilling conditions.

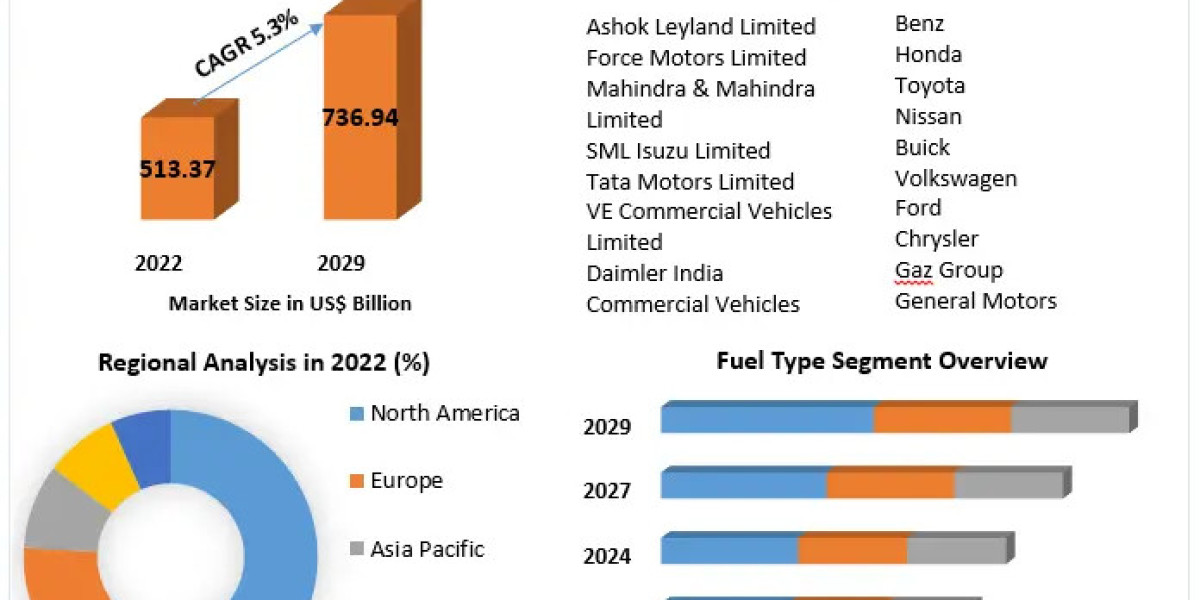

Wired Drill Pipe Market is expected to reach USD 1.1 Billion and is expected to grow at a CAGR of 3.2% during the forecast period 2023-2030.

The technology is becoming increasingly popular due to its ability to provide critical information about the drilling process, which can help to optimize drilling efficiency and reduce costs.

The connection of wired drill pipe is critical to ensure that the cable remains intact and can provide reliable communication between the surface and downhole equipment. There are several types of connections used in drill pipe, including threaded connections and non-threaded connections.

Threaded connections are the most common type of connection used in drill pipe. These connections consist of a male and female thread that screw together to form a tight seal. The threads are typically coated with a thread compound to prevent damage and ensure a tight seal.

Non-threaded connections, on the other hand, do not rely on threads to form a seal. Instead, they use a variety of mechanisms, such as mechanical clamps or slips, to hold the drill pipe together. Non-threaded connections are typically used in applications where the drill pipe is subjected to high stress or vibration.

Read Report Details @ https://www.marketresearchfuture.com/reports/wired-drill-pipe-market-4016

Drill pipe is used in the drilling process to transmit drilling fluid and rotational torque to the drill bit. The drill pipe is typically made of high-strength steel and is designed to withstand the extreme stresses and pressures of the drilling process.

To drill a hole for wires, a drill bit must be used to create a hole in the desired location. Once the hole has been drilled, the wires can be inserted and secured using appropriate connectors. It is important to ensure that the wires are protected from damage during the drilling process, and that they are securely fastened to prevent them from coming loose during operation.